Pipe stress analysis is the evaluation of how piping systems respond to loads such as pressure, temperature changes, weight, and external forces. It ensures that stresses, displacements, and forces remain within allowable limits defined by design codes and standards.

It is one of the most important items in piping design because it protects the system from failure, leakage, and excessive deformation. Proper pipe stress analysis helps ensure mechanical integrity, safe operation, equipment nozzle protection, and long-term reliability of the piping system under all operating and environmental conditions.

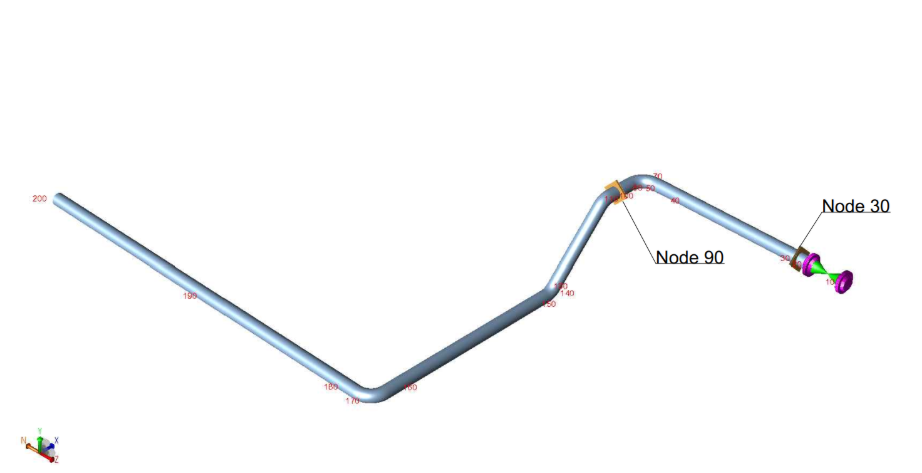

Our team has several years of experience and industry knowledge on how to analyse the piping system and come up with the unique solutions to make sure that the design is within the code compliance.

Pipe Stress Beyond Calculations

Why most pipe stress analysis issues are systemic, not analytical

In many industrial projects, pipe stress analysis is still perceived as a verification activity—something performed once the design is largely complete. However, experience documented across engineering literature and industrial project reviews consistently shows that most pipe stress issues are not rooted in calculation errors, but in fragmented technical decisions made much earlier in the design process.

Pipe stress as a late-stage activity in industrial projects

In many projects, pipe stress is introduced after routing, layout, and support concepts have already been fixed. When issues arise at that stage, they are often attributed to software limitations or calculation discrepancies. In reality, these issues usually originate from early assumptions that were never challenged or coordinated across disciplines.

If pipe stress is typically addressed late in your projects, this perspective may resonate with your experience.

Why pipe stress analysis issues keep reappearing

Post-project reviews and technical papers published within the ASME community show that piping-related rework is a recurring contributor to cost overruns and schedule delays. Excessive nozzle loads, overstressed supports, and unexpected thermal displacements are rarely caused by incorrect stress equations.

Instead, they are traced back to layout constraints introduced without flexibility considerations, support concepts defined before thermal behaviour was fully understood, and operating assumptions that were never revisited. In many documented retrofit projects, the stress analysis itself was technically correct, while the system assumptions were not.

Many organisations encounter the same pipe stress issues across different projects, despite using different tools or contractors.

Why pipe stress analysis is often addressed too late

Guidance accompanying ASME B31 piping codes has long cautioned against treating pipe stress as a late-stage compliance exercise. Nevertheless, in practice, stress analysis is still frequently scheduled after key design decisions have already been locked.

Once physical interfaces are fixed, stress analysis can no longer guide design—it can only react to it. This often results in forced redesign, additional supports, equipment nozzle reinforcement, or costly field modifications during construction.

If late-stage pipe stress findings are driving design changes in your projects, it may be worth revisiting how early assumptions are handled.

Explore how this applies in practice →

Pipe stress as an interface-driven engineering problem

Systems engineering literature, including the INCOSE Handbook and research on interface management applied to engineering design, consistently shows that complex systems tend to fail at their interfaces rather than within individual components.

Pipe stress behaviour is shaped precisely at those interfaces: between piping and equipment, between thermal expansion and support concepts, and between layout constraints and allowable movements. When these interfaces are not coherently addressed, stress issues emerge regardless of calculation accuracy.

This interface-driven view of pipe stress is well documented in engineering literature, yet still underapplied in day-to-day project execution.

From pipe stress analysis to engineering decisions

Engineering design literature consistently highlights that the purpose of analysis is decision support, not calculation alone. Projects that use analysis to inform early design decisions experience fewer late modifications and improved overall project stability.

Applied to pipe stress, this means using analysis to compare routing alternatives, assess support strategies, and understand mechanical consequences while design flexibility still exists.

At this point, pipe stress analysis stops being a calculation exercise and becomes a decision-support activity.

Discuss how this could support your project →

Software commonly used in pipe stress analysis

While pipe stress issues are rarely caused by software limitations, specialised analysis tools play an important role in modelling system behaviour, evaluating load cases, and documenting results. In industrial practice, a limited number of mature software packages are widely used for this purpose.

These tools enable the simulation of thermal expansion, pressure effects, sustained and occasional loads, and code compliance. However, the reliability of results depends primarily on modelling assumptions, boundary conditions, and engineering judgement.

- CAESAR II is widely used in oil & gas, power, and process industries for pipe stress analysis and ASME B31 code compliance.

- AutoPIPE is commonly applied in industrial and power generation projects, particularly where integration with structural and plant design environments is required.

- ROHR2 is widely used in European engineering contexts and supports advanced modelling of piping systems and compliance with international piping codes.

- PASS/START-PROF is applied in specific industrial sectors for modelling piping systems and generating stress results aligned with recognised piping standards.

Software enables analysis; engineering judgement determines its value.

How pipe stress analysis support is applied in practice

In practice, this approach translates into pipe stress support that engages early in the design process, clarifies assumptions before they propagate, and analyses mechanical behaviour in close coordination with layout and support design.

This role aligns with independent engineering advisory and owner’s engineering models described in industry literature, where the objective is early technical clarity rather than late-stage firefighting.

If you are looking for early technical clarity rather than late-stage firefighting, we can discuss how this type of pipe stress support fits your context.

Who this pipe stress engineering approach is for

This approach is relevant for complex industrial projects where piping behaviour has a material impact on safety, reliability, cost, or schedule. It is less relevant for purely box-checking exercises or systems with limited mechanical interaction.

If this description matches how your projects operate, a conversation is likely to be productive.

A closing reflection on pipe stress analysis

As repeatedly noted in engineering project post-mortems, late technical surprises are often the result of early decisions being revisited under pressure. Pipe stress analysis, when treated as an isolated calculation, tends to reveal problems too late. When treated as part of an integrated technical system, it helps prevent those problems from arising in the first place.

Selected references and further reading

ASME B31 Piping Codes and Companion Guides – Design, flexibility, and stress considerations in industrial piping systems.

ASME PVP Conference Proceedings – Lessons learned from piping failures, retrofits, and stress-related rework.

INCOSE Systems Engineering Handbook – Systems integration and interface-driven failure mechanisms.

Interface management research applied to engineering design – Coordination of technical interfaces in complex projects.

Engineering design decision-making literature – Analysis as a tool for early technical decisions rather than late-stage verification.